- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Cina Alumina (Al2O3) Produsen, Pemasok, Pabrik

- View as

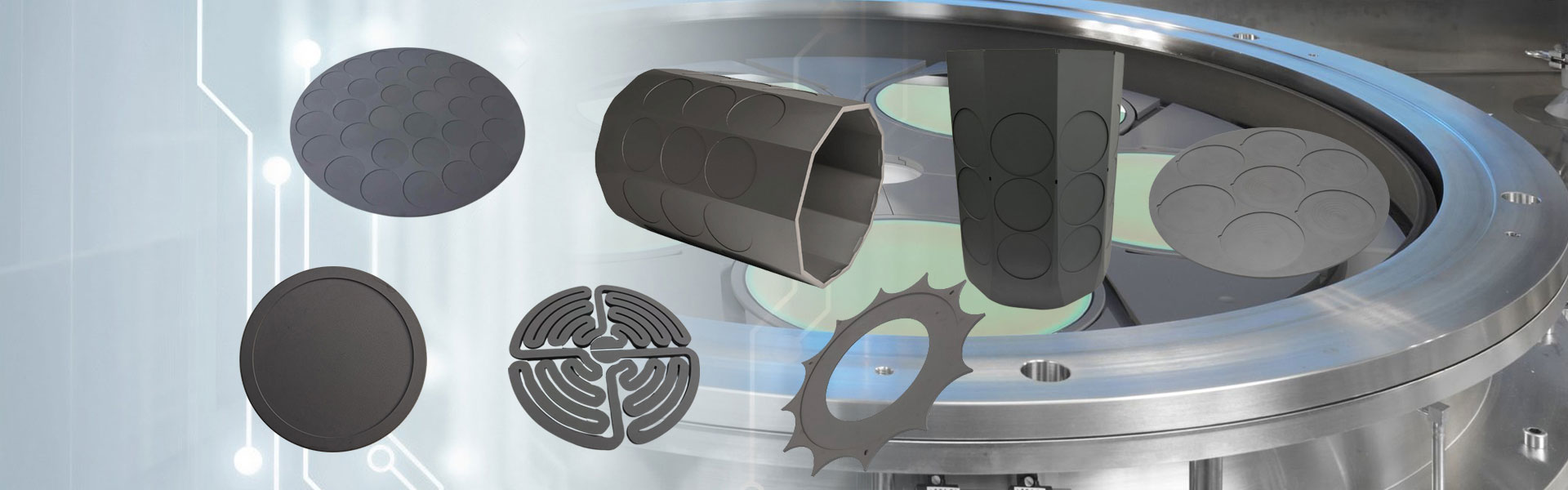

Efektor akhir keramik alumina

Semicorex Alumina Ceramic End Effector adalah komponen rekayasa presisi yang dirancang khusus untuk penanganan wafer yang andal dan bebas kontaminasi dalam manufaktur semikonduktor dan aplikasi terkait.*

Baca selengkapnyamengirimkan permintaanChuck Keramik Berpori

Chuck Keramik Berpori Semicorex (Vacuum Chuck) adalah alat presisi tinggi yang dirancang untuk menahan wafer dengan aman selama proses pembuatan semikonduktor. Dengan memilih Semicorex, Anda mendapatkan keuntungan dari solusi yang menawarkan kinerja, daya tahan, dan opsi penyesuaian yang luar biasa, memastikan peningkatan efisiensi produksi dan standar kualitas yang konsisten.*

Baca selengkapnyamengirimkan permintaanChuck Vakum Alumina

Semicorex Alumina Vacuum Chuck adalah komponen rekayasa presisi yang dirancang untuk menahan wafer atau substrat dengan aman selama proses semikonduktor kritis dan manufaktur presisi. Dengan komitmen Semicorex terhadap bahan berkualitas tinggi dan teknik manufaktur mutakhir, Alumina Vacuum Chuck kami memberikan keandalan, presisi, dan kinerja tak tertandingi untuk aplikasi Anda yang paling menuntut.*

Baca selengkapnyamengirimkan permintaanChuck Vakum

Semicorex Vacuum Chuck adalah komponen berkinerja tinggi yang dirancang untuk penanganan wafer yang aman dan presisi dalam manufaktur semikonduktor. Pilih Semicorex untuk solusi kami yang canggih, tahan lama, dan tahan kontaminasi yang menjamin kinerja optimal bahkan dalam proses yang paling menuntut sekalipun.*

Baca selengkapnyamengirimkan permintaanCincin Isolasi Alumina

Cincin Insulasi Alumina Semicorex digunakan sebagai isolator pada berbagai komponen listrik, sifat insulasi listriknya yang sangat baik memastikan kinerja yang andal dalam aplikasi yang mengutamakan pencegahan konduksi listrik.

Baca selengkapnyamengirimkan permintaanPembawa Pemoles Wafer Alumina

Penerapan Semicorex Alumina Wafer Polishing Carrier di berbagai industri, mulai dari semikonduktor hingga fotovoltaik, memainkan peran penting dalam proses penggilingan dan pemolesan mekanis kimia (CMP) wafer.

Baca selengkapnyamengirimkan permintaan