- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Cina Alumina (Al2O3) Produsen, Pemasok, Pabrik

Alumina ceramics are a type of advanced ceramic material that is primarily made of aluminum oxide and the general purpose of ceramists. They are in great demand because of their remarkable comprehensive properties, some of which include high hardness, high wear resistance, and high temperature resistance. These will maintain their structure at very high temperatures. Additionally, alumina ceramics have high electrical insulation and chemical resistance, and very high mechanical strength. While brittleness will limit them. They possess all those properties which has resulted in alumina ceramics playing a central role in the semiconductor industry.

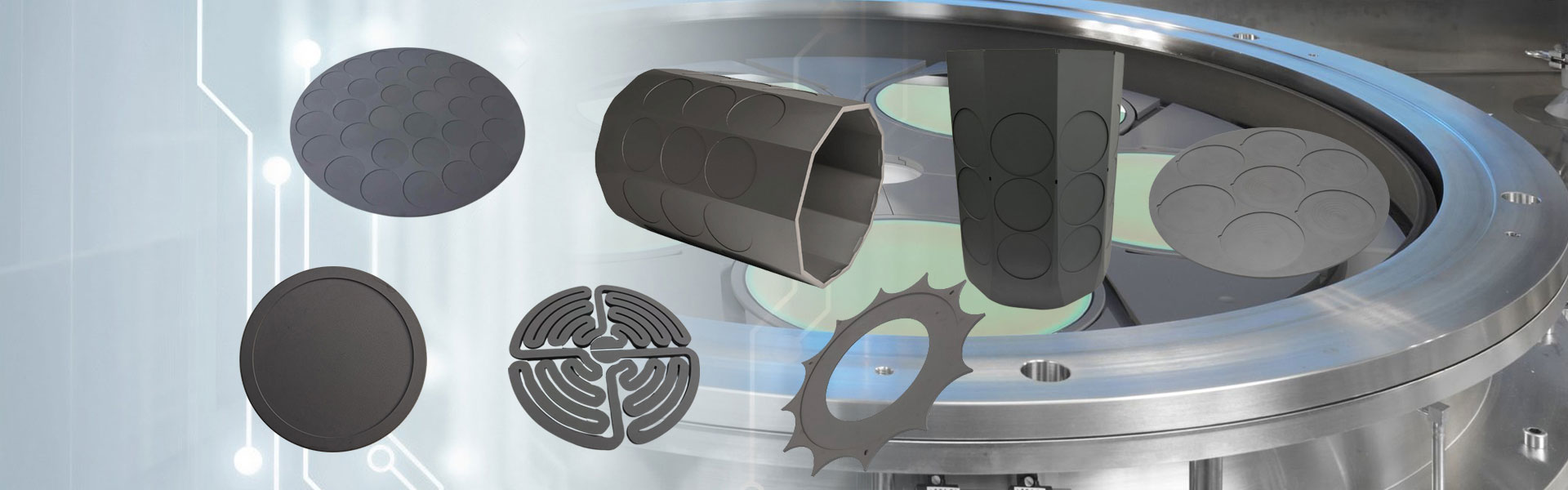

The vacuum chuck will be attached to the vacuum equipment via a connecting pipe. When the chuck comes in contact with the workpiece, i.e., a sheet or film, the vacuum equipment will activate and draw negative pressure in the chuck. The workpiece is carried by atmospheric pressure thus it will cling firmly to the chuck allowing the processing to go on without issue. When the workpiece is done being processed the vacuum machine will stop and the chuck will gradually fill with air. The workpiece will separate of its own accord thus finishing the clamping, processing and handling processes.

Black Alumina ceramic is one of the primary materials used in vacuum chucks. It is primarily composed of Al2O3, with transition metal oxides as colorants and sintering aids added. The process is then sintered at a specific temperature. Vacuum chucks made from porous ceramic feature ultra-fine micrometer-level pores and spacing, enabling reliable handling of thinner and more delicate workpieces. Furthermore, these chucks can accommodate workpieces of varying sizes, eliminating the need to maintain a fixed set of shapes and sizes for each workpiece, thus saving costs and improving efficiency.

Alumina ceramics have a high elastic modulus and specific stiffness, are resistant to deformation, and have a low coefficient of thermal expansion and high thermal stability. They are an excellent structural material and are currently widely used in aviation, aerospace, petrochemicals, machinery manufacturing, the nuclear industry, and microelectronics.

Alumina ceramic components offer excellent properties such as high hardness, high mechanical strength, exceptional wear resistance, high temperature resistance, high resistivity, and excellent electrical insulation. They can meet the complex performance requirements of semiconductor manufacturing in special environments such as vacuum and high temperature. They play an irreplaceable and important role in semiconductor manufacturing production lines, covering nearly all semiconductor manufacturing equipment and serving as key components. Alumina ceramic components are primarily categorized by application, including annular and cylindrical types, airflow guides, load-bearing and fixed types, hand-grip gaskets, and modules.

- View as

Papan Serat Alumina Polikristalin

Papan serat alumina polikristalin adalah bahan pelat tahan api berkinerja tinggi dengan ketahanan guncangan termal yang sangat baik, ketahanan korosi yang kuat, dan ketahanan oksidasi yang unggul. Kinerja tahan api ini membuatnya banyak digunakan dalam lingkungan bersuhu tinggi yang menantang, termasuk tungku bersuhu tinggi, kiln bersuhu tinggi, reaktor bersuhu tinggi, saluran pipa bersuhu tinggi, pintu tungku bersuhu tinggi, dinding tungku bersuhu tinggi. Memilih Semicorex, Anda akan mendapatkan keuntungan dari harga yang sangat hemat biaya, layanan penyesuaian pribadi yang dipersonalisasi, dan kualitas produk yang luar biasa.

Baca selengkapnyamengirimkan permintaanNozel Keramik yang Dapat Disesuaikan

Diproduksi dengan perhatian cermat terhadap detail, nozel keramik yang dapat disesuaikan dari Semicorex adalah solusi jenius untuk mengontrol laju aliran gas dan cairan dengan keseragaman dan presisi yang tak tertandingi. Semicorex menantikan konsultasi Anda lebih lanjut.

Baca selengkapnyamengirimkan permintaanChuck Elektrostatis Keramik

Chuck elektrostatik keramik semicorex adalah komponen adsorpsi elektrostatik presisi yang terbuat dari keramik alumina dan aluminium nitrida berkinerja tinggi, yang menggunakan prinsip adsorpsi elektrostatik untuk menjepit dan memperbaiki wafer. Ini banyak digunakan di bidang manufaktur semikonduktor. Semicorex memiliki teknologi canggih, bahan berkualitas tinggi, dan produk hemat biaya. Kami berharap dapat menjadi mitra pemasok terpercaya Anda di Tiongkok.

Baca selengkapnyamengirimkan permintaanManipulator Keramik Alumina

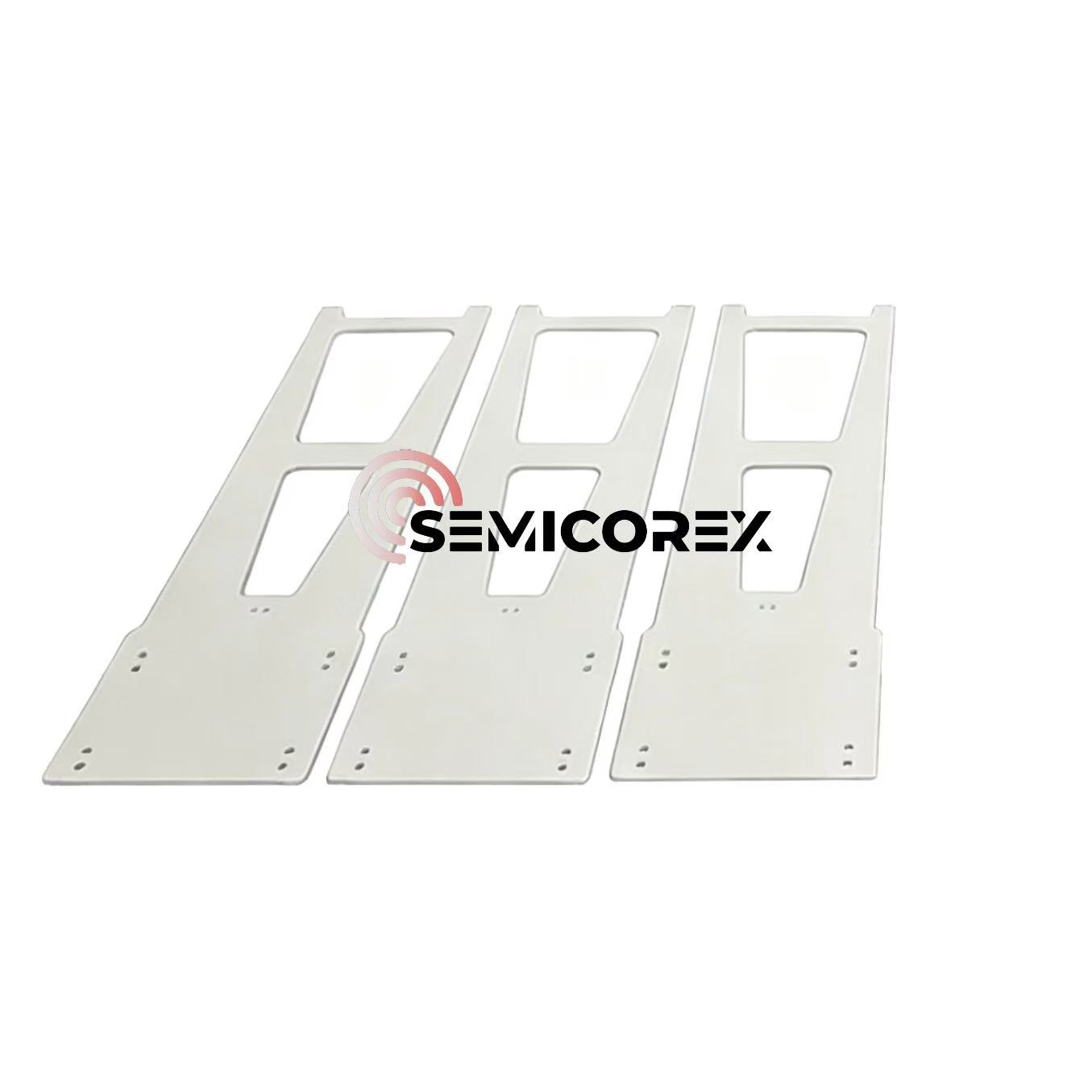

Manipulator keramik alumina Semicorex adalah komponen peralatan semikonduktor berkinerja tinggi yang terbuat dari alumina dengan kemurnian tinggi, dirancang khusus untuk penanganan wafer bebas kontaminasi secara presisi. Manipulator ini memiliki karakteristik kebersihan luar biasa, stabilitas unggul, presisi tinggi, peningkatan efisiensi, dan kinerja andal, menjadikannya pilihan ideal Anda.

Baca selengkapnyamengirimkan permintaanPiring dasar pemasangan alumina

Pelat dasar pemasangan alumina semikorex adalah komponen keramik berkinerja tinggi yang dirancang untuk penanganan wafer yang tepat dalam manufaktur semikonduktor. Kekuatan, isolasi, dan stabilitas termal yang unggul membuatnya ideal untuk menuntut lingkungan otomatisasi ruang bersih.*

Baca selengkapnyamengirimkan permintaanLengan Robot Alumina

Semicorex Alumina Robot Arm adalah komponen keramik berkinerja tinggi yang dirancang untuk penanganan wafer yang tepat dalam manufaktur semikonduktor. Kekuatan, isolasi, dan stabilitas termal yang unggul membuatnya ideal untuk menuntut lingkungan otomatisasi ruang bersih.*

Baca selengkapnyamengirimkan permintaan